Agnflow Centre Pivot Irrigation systems and centre pivot system parts outlet where we provide new and used centre pivots and lateral irrigators. Agnflow can tailor-make your new or used centre pivot to suit your irrigation needs. If you are looking for farm irrigation systems Agnflow can assist you with the right irrigation choice. Efficacy in water use and efficiency in energy is the most critical drivers for any irrigation farm. For centre pivot sprinklers, lateral move irrigation, towable centre pivots, and pivoting lateral irrigators are just some of the options we can provide.

At Agnflow we are a recognised dealer of new and used centre pivots throughout Australia, Our customer base covers Victoria, NSW, QLD, WA, Tasmania and New Zealand. We supply many aftermarket Centre pivot parts as well to suit many of the leading brands and a very competitive price. We offer replacement parts such as centre drives, wheel gears, span parts, electrical parts, tower boxes, centre pivot tires and rims.

Through long-established contacts with various manufacturers, we can provide a full range of centre-pivot parts and services through our centre-pivot parts warehouse. Agnflow can help you get your centre pivot and lateral move system up and running again.

Agnflow is backed by over 30 years of centre-pivot knowledge and a passion for water savings.

Disclaimer

Agnflow PTY LTD has no affiliation with Reinke, Valley/Valmont, TL, Lyndsay/Zimmatic, Pierce/Western. None of our aftermarket structural parts or others is manufactured by Valley/Valmont, Reinke, TL, Lyndsay/Zimmatic, Pierce/Western or in any way endorsed and or certified by Reinke, Valley/Valmont. TL, Lyndsay/Zimmatic, Pierce/Western. Agnflow PTY LTD is an independent supplier of aftermarket parts and services.

Agnflow can help with new and used centre pivots and lateral move irrigators. Agnflow is Australia’s premier pivot irrigation manufacturer with its AL13-G range of aluminium centre pivots. Agnflow is also a provider of Centre pivot irrigator parts from span parts to suit used Valley pivots, used Reinke pivots, used Lyndsay pivots, used TL systems and more. If anyone is looking for a cost-effective option for pivot irrigation parts and repairs, and farm watering systems then we can help save our customers money.

Disclaimer

Agnflow PTY LTD has no affiliation with Reinke, Valley/Valmont, TL, Lyndsay/Zimmatic, Pierce/Western. None of our aftermarket structural parts or others are manufactured by Valley/Valmont, Reinke, TL, Lyndsay/Zimmatic, Pierce/Western or in any way endorsed and or certified by Reinke, Valley/Valmont. TL, Lyndsay/Zimmatic, Pierce/Western. Agnflow PTY LTD is an independent supplier of aftermarket parts and services.

At agnFlow, our irrigation consultants we offer a range of irrigation services to help meet your needs, from our consultancy service, where we can offer on farm advice and planning for your project, to emergency centre pivot repairs for that unfortunate accident that requires a knowledgeable response.

We also offer day to day centre pivot and lateral move irrigator servicing, including checking mixed flow pumps, irrigation motors, pipes and fittings to keep your system in good condition and ready for your next crop.

Disclaimer

Agnflow PTY LTD has no affiliation with Reinke, Valley/Valmont, TL, Lyndsay/Zimmatic, Pierce/Western. None of our aftermarket structural parts or other are manufactured by Valley/Valmont, Reinke, TL, Lyndsay/Zimmatic, Pierce/Western or in any way indorsed and or certified by Reinke, Valley/Valmont. TL, Lyndsay/Zimmatic, Pierce/Western. Agnflow PTY LTD is an independent supplier of aftermarket parts and services.

today and let us solve your irrigation headaches.

Irritech now have relesed a new version of the Irritech V Series Channel feed lateral move irrigator.

Thank you for contacting agnFlow, we will be in touch with you as soon as possible.

Discover AgnFlow: Your Partner in Agricultural Innovation

At AgnFlow, we specialize in providing comprehensive agricultural solutions, focusing on irrigation systems, project management, and expert advice. With our extensive experience and strong supplier relationships, we offer a diverse range of products at competitive prices.

Why Choose AgnFlow?

Comprehensive Irrigation Solutions

We are deeply integrated into every facet of irrigation and agricultural upgrades. AgnFlow is continuously expanding its product range to include:

We proudly serve clients throughout Victoria, New South Wales, South Australia, and beyond, with a commitment to Australia-wide service and international shipping.

Expert Design & Advice

Our experienced design team is dedicated to providing the best irrigation solutions tailored to your needs. Whether you’re upgrading an existing system or installing irrigation for the first time, our expertise in Center Pivot and Lateral Move Irrigation ensures you receive unparalleled guidance and support.

Service & Repairs

In addition to our product offerings, AgnFlow provides comprehensive service and repairs. We maintain a large inventory of after-market parts for Center Pivot and Lateral Move systems, ensuring quick and efficient maintenance support.

Contact AgnFlow Today

Ready to learn more about our products and services? Contact our team to discover how AgnFlow can support your agricultural needs with top-tier solutions and unmatched expertise.

—

Feel free to make any adjustments to better align with your branding or specific offerings. This version aims to be more engaging and clear, highlighting AgnFlow’s strengths and broad capabilities.

AgnFlow is continually looking for opportunities to increase the distribution of our products by partnering with the right businesses in the right areas. With a years of experience for irrigation and international trading, agnFlow is your one-stop-supplier for your irrigation needs.

Becoming a reseller of the agnFlow product range provides you with complete access to range of irrigation and agricultural related products from quality suppliers from all over the world.

Our objective at agnFlow is to build strategic relationships with our resellers, by continually exceeding our customers’ expectations in all aspects of our service and continuing to provide consistency for our customers with our products.

To enquire about becoming a part of the agnFlow reseller network, please contact us for more information.

Our agnFlow dealers have extensive experience in the provision of irrigation and associated products to the agriculture sector. Please contact us if you’d like to know more about our dealers or the agnFlow company and its products.

Your centre pivot is just like any other farm machine, it needs servicing to keep it in top running condition and ready for your next crop.

Our centre pivot and lateral move irrigator servicing is available for Victoria, New South Wales, South Australia, we can also cover the rest of Australia if required.

agFlow offers a full range of center pivot servicing, which includes such things as oil change in the wheel drives and centre drives, checking the drive couplings, tyre pressures and checks, electrical and nozzle checks. We can also supply irrigation drive components and a range of irrigation pipes and fittings.

If your centre pivots or lateral move irrigation system has been neglected for a while, or just needs a good service, please contact us.

AgnFlow can provide after market pipes and span span parts for many systems. We supply after market pipes for Valley, Reinke, Lyndsay, TL . If your centre pivot or lateral move irrigator has a problem, we can get you up and going as soon as possible.

Centre pivots and lateral move irrigation products are just another piece of farm equipment and suffer from a range of problems such as storm damage, farmer damage and like us old age.

If your system is showing signs of age, and you know its only a matter of when, not if you will find it on the ground, then talk to us and we will put a plan in place. We have aftermarket irrigation span parts including Reinke E65 E 80 , Lyndsay, Valley 8120 8000 style Pipe and many more options.

Don’t wait until its too late as most of the time your system will fall when we are using it and parts and service is critical.

Our irrigation consultants also specialise in insurance repairs for centre pivots and lateral move irrigators and can help you with your claim if you’re having difficulty.

Disclaimer

Agnflow PTY LTD has no affiliation with Reinke, Valley/Valmont, TL, Lyndsay/Zimmatic, Pierce/Western. None of our aftermarket structural parts or other are manufactured by Valley/Valmont, Reinke, TL, Lyndsay/Zimmatic, Pierce/Western or in any way indorsed and or certified by Reinke, Valley/Valmont. TL, Lyndsay/Zimmatic, Pierce/Western. Agnflow PTY LTD is an independent supplier of aftermarket parts and services.

The experienced irrigation consultants at agnFlow can provide a full consultancy service for irrigation upgrades, farm reconfiguration, new farm purchases and government grants (when available).

Through our relationship with valued irrigation planners, farm survey providers and a strong background in irrigation services which steams back nearly 50 years, agnFlow through its partners can give you the best advice.

Our irrigation consultants can help with the following:

If you are looking at irrigation for your farm or have a need for one of the above, please call agnFlow’s irrigation consultants and let us help you get the best value for money and a happy result.

At Agnflow, we’ve designed our Lateral Move Irrigation systems with advanced technology to make irrigation easier for modern farms. Perfect for large paddocks, our systems focus on delivering only the necessary functions for efficient and hassle-free water management.

Our lateral move irrigation systems available in galvanized and aluminium version, powered by cutting-edge local Australian GPS technology, to ensure consistent coverage while simplifying the irrigation process.

At Agnflow, we believe in simplifying irrigation through technology that’s advanced, effective, and easy to use.

With over 35 years of expertise in the field of irrigation solutions, Agnflow sets itself apart as a comprehensive provider, offering not only top-of-the-line irrigation systems but also reliable pump and generator sets. Our commitment extends beyond mere product supply; we are dedicated to assisting our clients in establishing complete irrigation setups from initiation to full functionality. With Agnflow, rest assured that your irrigation needs will be met with precision and excellence, ensuring seamless operation from start to finish.

This is a customized installation of a cutting-edge pump set with a generator, to work together with an Irritech 10-Span centre pivot irrigation system. What sets this installation apart is incorporating a VFD controller in the pump set. The VFD controller offers unparalleled precision and control, allowing for optimized performance and energy efficiency. By implementing this innovative technology, we not only enhance the reliability and longevity of the irrigation system but also ensure cost-effectiveness and sustainability in the long run.

At Agnflow, we take pride in offering a full range of services and customized designs to address all your irrigation needs. Our focus is not just on delivering products but on creating solutions that are tailor-made to suit your farm and crop requirements perfectly. At Agnflow, we continue to demonstrate our commitment to pushing the boundaries of irrigation technology and providing our clients with the best-in-class solutions.

For all your irrigation needs, trust Agnflow to deliver excellence, innovation, and reliability every step of the way.

Hurry Up! Time is running out on our biggest sale of the year!

With just 2 weeks left until the EOFY2024, this is your final opportunity to grab incredible deals on our top products. Don’t miss out on the chance to save big and get the best value for your money.

🛒 Why Shop Our EOFY Sale?

• Unbeatable Prices: Enjoy big discounts on selected items.

• Wide Selection: From our Australian-Made Aluminium Irrigation System to the imported Irritech Galvanized and Polylined irrigation system, there’s something for everyone.

• Limited Stock: Our hot deals are flying off the shelves. Once they’re gone, they’re gone for good!

💡 Pro Tip: Take advantage of these amazing deals to stock up on essentials, upgrade your irrigation system or even get ahead some repipe stock for upcoming occasions.

⌛ Don’t Wait – Act Now!

• The clock is ticking, and these deals won’t last forever. Visit our shop today and make the most of our EOFY sale before it’s too late.

• Shop Online: Visit www.agnflow.com.au

• Visit Us: Come to our store at Ascot and enjoy the discounts in person.

Give us a call now and discuss your irrigation needs.

Remember, once the EOFY sale is over, these offers will be gone. This is your last call to score big and save even bigger!

👉 Shop Now and make the most of these fantastic deals!

Attention all farmers and growers in the Kerang region of Victoria: there’s exciting news on the horizon! Agnflow is thrilled to announce the installation of another 10-span galvanized Irritech centre pivot in the heart of Kerang. This latest addition to the agricultural landscape promises enhanced efficiency, improved irrigation capabilities, and increased crop yields for local farmers.

What sets this Irritech centre pivot apart is its Valley-style structure, a hallmark of reliability and performance in the irrigation industry. Agnflow’s collaboration with Irritech since 2018 has provided us with unparalleled expertise in these systems, allowing us to understand them inside and out. Whether you’re a seasoned irrigation expert or considering a Valley-style import machine for the first time, Agnflow is your go-to partner for expert guidance and support.

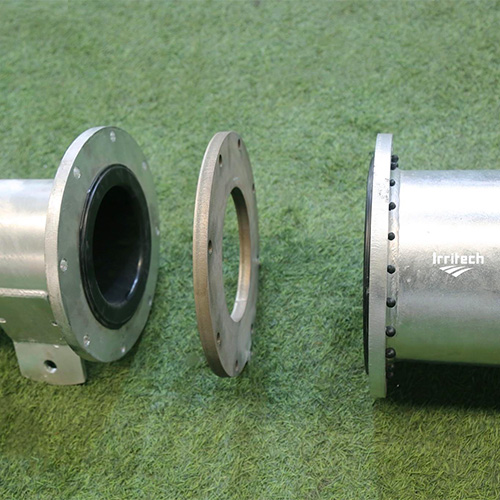

But that’s not all – all Irritech irrigation systems carry the original UMC gearbox and centre drive, ensuring durability, reliability, and consistent performance season after season. With Komet sprinklers and an end gun included as standard features, these systems are designed to meet the diverse needs of modern farming operations.

And now, we’re thrilled to announce that Irritech centre pivots are also available in polylined systems, offering even greater versatility and durability. Available in 6 5/8″ and 8 5/8″ configurations, these polylined systems combine the proven performance of Irritech pivots with the added benefits of poly lining, ensuring resistance to corrosion and wear for years to come.

The installation of this 10-span galvanized Irritech centre pivot represents a significant milestone in our ongoing commitment to revolutionizing irrigation technology in Australia. By harnessing the latest advancements in pivot design and engineering, we aim to empower local farmers with the tools they need to thrive in an ever-changing agricultural landscape.

We invite farmers and growers in Kerang and beyond to explore the benefits of Irritech centre pivots with Agnflow. Our knowledgeable team is on hand to provide personalized advice, tailored solutions, and unrivalled customer support every step of the way. Whether you’re looking to upgrade your existing irrigation system or invest in a new solution, we’re here to help you achieve your goals.

Join us in celebrating the installation of another 10-span galvanized Irritech centre pivot in Kerang, VIC. Together, we’re paving the way for a brighter, more sustainable future for agriculture in Australia. Get in touch with Agnflow today to learn more about our partnership with Irritech and how we can support your irrigation needs.

Agnflow, the leading provider of innovative irrigation solutions, recently graced the South East Field Days at Lucindale, South Australia, with a display that turned heads and captured imaginations. Boasting an array of state-of-the-art offerings, Agnflow showcased our commitment to excellence in irrigation technology, drawing attention to our Australian-made aluminium centre pivot and the acclaimed Irritech galvanized and polylined pivot system.

One of the standout attractions at Agnflow’s exhibit was our Australian-made aluminium centre pivot. Crafted with precision and built to withstand the rigors of agricultural use, this pivot system exemplifies durability, reliability, and performance. Visitors had the opportunity to witness its seamless operation and learn about its unique features designed to optimize water distribution and enhance crop yields.

In addition to our flagship aluminium centre pivot, Agnflow also showcased the Irritech galvanized and polylined pivot system. Renowned for its robust construction and superior corrosion resistance, this system offers farmers a dependable solution for long-term irrigation needs. Attendees were impressed by its advanced design and efficiency, recognizing it as a testament to Agnflow’s commitment to delivering cutting-edge technology to the agricultural sector.

But Agnflow’s offerings didn’t stop there. Recognizing the diverse needs of farmers and growers, the company also presented our comprehensive range of aftermarket parts for different brands of pivot systems. With a focus on quality, compatibility, and performance, Agnflow’s aftermarket parts ensure seamless integration and optimal functionality, providing farmers with peace of mind and reliability in their irrigation systems, such as Valley, TL, Reinke, Zimmatic, and Bauer style systems.

Throughout the event, the Agnflow team stood ready to engage with attendees, offering expert advice, answering questions, and providing personalized recommendations tailored to individual farming operations. Our dedication to customer satisfaction and our passion for innovation shone through, leaving a lasting impression on all who visited our exhibit.

As the South East Field Days came to a close, Agnflow emerged as a beacon of excellence in the field of irrigation technology. Our commitment to delivering top-tier solutions, combined with our unwavering dedication to customer service, reaffirmed our position as a trusted partner for farmers and growers across Australia.

For all your pivot needs, from cutting-edge pivot systems to reliable aftermarket parts, look no further than Agnflow. With our expertise and innovation, we are poised to revolutionize the way you irrigate, ensuring a sustainable and prosperous future for agriculture.

The fact that the pivot works automatically and has great reliability means that the farmer may tend to forget that there are, nevertheless, certain maintenance operations to be carried out. This aspect must not be neglected even though the recommended frequency is only once a year.

The Centre Pivot irrigation method is very widespread throughout the world because this technique has many advantages:

• automatic operation requiring very little maintenance;

• irrigation quality: perfect distribution and ideal application rate with the new generation of sprinklers;

• saving on water and energy because it operates at low pressure;

• optional new equipment allows for practically the whole field to be irrigated;

• low annual maintenance costs;

• very reliable.

The advantages of regularly maintaining the pivot. Programming the annual maintenance operations will guarantee greater reliability and a longer life for the equipment. Irrigation is a crop-growing technique and just like fertilisation or weeding it will greatly contribute towards the final yield. It is vital to avoid break-downs during the season.

The pivot’s return on investment will then be so much better.

Monitoring and control of the nozzles. This is also an important aspect to be checked because it is the nozzles that control the quantity, quality and uniform distribution of the water application programmed by the user. Apart from simply checking the system visually to ensure that it is working properly, it is also recommended that the installation’s flow rate should be checked; an increase or decrease in the flow rate could be caused by use or by a partial blockage of the nozzles. In this case, the hydraulic performance of the pivot will have changed.

It is still quite difficult to provide standard guidelines regarding the frequency of changing the nozzles, sprinklers and pressure regulators.

The conditions of use are very variable and must be considered in context according to:

• operating pressures

• number of operating hours per year

• water quality

• type of sprinkler used

Generally, we can assume that the rotating sprinklers have a working life of 10,000 hours and the impact sprinklers 7,000 to 8,000 hours.

In the regions where irrigation is supplementary, the farmers push their equipment to the limit as far as the life span and performance of the sprinklers and pressure regulators are concerned, because the crop will not suffer unduly even if the installation is operating below par. However, in areas where more water is required or for higher-margin crops, the producers have to ensure that the pivot is checked regularly and that the nozzles are replaced more frequently.

We can quote the example of the North-east Pacific zone of the United States where many farmers grow potatoes. This root vegetable is the primary crop rotated every 4 to 5 years with other irrigated crops. The pivots operate for 2,000 to 2,500 hours per year. The farmers in this area replace the sprinklers and pressure regulators in the spring when they plant the potatoes, so as to ensure optimum irrigation for the most important crop in the rotation.

In conclusion, as with any mechanical or electrical equipment, the pivots require regular check-ups. These annual operations are very simple to carry out. On the large farms, where there are a large number of pivot systems, the farmers carry out their own maintenance and replace the faulty parts with spares that they often have in stock themselves.

For smaller units, the installation dealers organise wintering sessions for their customers.

For the nozzles, replacements are often motivated nowadays by the desire to be able to use rotating sprinklers on the down pipes, instead of the fixed spray versions. This, at the same time, allows for the pivot to be modernized by using a far more efficient technique.

Note: The above article is quoted from “Irrigazette”-the leading international irrigation magazine.

Good welding is essential for the effective operation and longevity of a center pivot irrigation system. Center pivots are complex systems that rely on a range of interconnected components to distribute water evenly across large agricultural fields. The pipes, trusses, towers, and other components of the system must be securely and reliably connected to ensure that the system operates smoothly and efficiently.

One of the most critical components of a center pivot irrigation system is the truss rods that support the weight of the system. These truss rods must be securely attached to the pivot point and the towers to ensure that the system is stable and does not collapse under its own weight. Good welding is essential to ensure that these connections are strong and reliable, and that the truss rods do not become loose or disconnected over time.

In addition to truss rods, good welding is also important for the pipes that make up the system. Pipes must be connected securely to prevent leaks, which can cause water waste and reduce the efficiency of the system. Good welding can also prevent corrosion and rust, which can weaken the pipes and cause them to fail over time.

Overall, good welding is essential for the effective operation and longevity of a center pivot irrigation system. It ensures that the system is stable, reliable, and efficient, and helps to maximize the productivity of agricultural operations. This is why it’s important to get parts for center pivot in good welding condition, Agnflow use very experienced welders both for aluminium also metal materials to make sure all parts and center pivot we made are excellent welded.

If you’re in the agriculture industry, you know how important it is to have a reliable and efficient irrigation system. One of the most common types of irrigation systems used in large-scale farming is the centre pivot, which consists of a long span of pipes and sprinklers that pivot around a central point, providing water to crops in a circular pattern. And if you’re looking to upgrade your centre pivot system, you might want to consider Agnflow’s AL13 Aluminium Center Pivot.

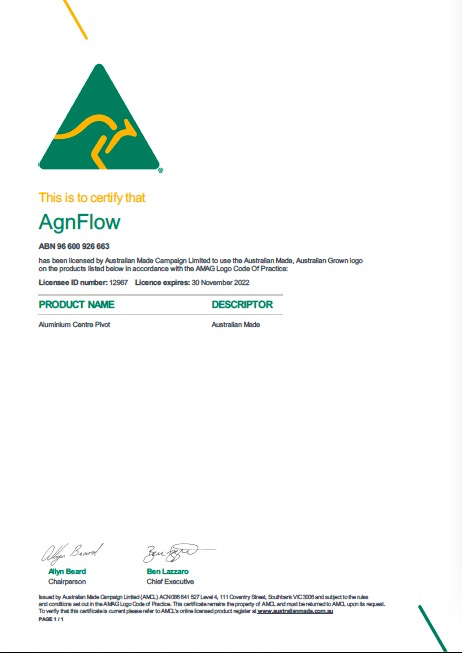

One of the key features of Agnflow’s AL13 is that it’s made from high-quality, Australian-made aluminium. Our pivot system Agnflow AL13-G gives way to uncomplicated design and a commonsense approach to utilizing as much Australian-made material as possible, we secured our Australian-made registration in 2021. We have been supported well by BlueScope Steel and their Australian-made Aluminium and steel products. This makes it lightweight, durable, and resistant to corrosion and rust. Unlike traditional steel centre pivots, the AL13 won’t be affected by moisture, chemicals, or other elements commonly found in agricultural environments. This means that you can rely on the AL13 to provide long-lasting, trouble-free service for years to come.

Another advantage of the AL13 is its modular design. Our system is available in 150mm and 203mm versions with span lengths from 36 – 48 meters. Using a proven truss and brace design along with one of the strongest tower support systems made today the AL13-G is a very robust system.

In addition to its durability and versatility, the AL13 is also designed for efficiency. It uses low-pressure sprinklers, which means that you can conserve water while still providing adequate irrigation to your crops. And because it’s made from lightweight aluminium, it requires less energy to move than a heavier steel pivot, which can help reduce your overall energy costs.

Overall, if you’re looking to upgrade your centre pivot system, the Agnflow AL13 Aluminium Center Pivot is definitely worth considering. Its lightweight, durable construction, modular design, and efficient sprinkler system make it a top choice for farmers and agricultural professionals looking to improve their irrigation systems. And because it’s made in Australia, you can be sure that you’re getting a high-quality, locally-made product that’s built to last.

For agnFlow, it is one of ur company’s visions to have our own production line in Australia and to integrate our over 30 years of experience about centre pivot and lateral move irrigation system, into the design and development of our own brand, and now it comes true! After two years of continuous testing and improvement, we launched our own brand aluminium centre pivot irrigation system AL13-G in 2021, successfully applied for “Australian Made” Certificate. This is and affirmation of the quality of our pivots and ensures that the materials we used to make our centre pivot are from Australian locally. We are very proud to be a part of “Australian Made”.

This AL13-G model aluminium center pivot irrigators are new Australian designed and manufactured, more details please check on our product pages.

Agnflow P1962-G Australian Proud Centre pivot

1.fixed centre point available in 6 5/8″ and 8 5/8″.

2.Stainless steel main control panel

3.Flexible joint: the coupling between spans with internal joint and flexible hose, placed in the centre of the pipeline, allows side, up and down and rotational movements, with reduced effects on the structure and hose longevity. No other system is so efficient in hilly terrain.

4.Single tower legs, made of 6″ U-beam, fastened by 4 bolts to a sturdy support welded to the pipe, provides the tower greater strength compared to other systems using a single bolt and a structural shape made from steel angles of thin thickness.

5. Smart control: you can operate your pivot on phone or computer any time you want, saving time and money.

6. Sprinkler package available in i-Wob or Komet.

Another 6 Span Agnflow P1962-G Australian Proud Centre Pivot Being Assembled by agnflow team.

Agnflow P1962-G Australian Proud centre pivot are designed and put up here in Australia locally, within the conditions and requirements of Australia. All our pivot runs with UMC centre drive and gearbox, Senninger sprinkler package, Xcad end gun, and Bermad Valves, heavy 14.9-24 tire for standard, turf tire for optional if you need.

Agnflow P1962-G Australia Proud Centre Pivot using senninger bubbles for high water efficiency output, check out details on the below video.

agnFlow team organised the Irritech V series demo centre pivot on our own paddock for testing, now you are welcomed to come to visit us and check out this pivot details for any interests.

Irritech V Series Centre Pivot, we have the very good packing standard for international market container shipping, with the wheeled pallet at bottom, it’s very easy to unload the parts at your paddock or warehouse.

As Irritech steel structure are same as Valley style centre pivot, so if you know Vally pivots, it won’t have any issue to assemble them, don’t worry even you have no experience with Valley style pivot, just follow our installation manual, you will find out its too easy to put them up. We had 2 workers to put up this 4span pivot up within 3days, you will need a telehandler, will help you a lot. If you can not do installation by yourself, no worries, contact with our agnflow team, we could arrange the assemble for you at your paddock.

If you have any issue when you wiring up the electric parts, call agnFlow for electrical service, we will send our experienced technician for help.

For the sprinkler, we will give you the advise depend on your soil quality and plant you having in your paddock, for this demo machine, we put up with Senninger LEPA ( Low Energy Precision Application), with LEPA heads, at least 20 percent more water reaches the soil than with conventional spray nozzles. More details please find out on our website about LEPA introduction.

agnFlow not only established for centre pivot selling, we are focus on supplying the sustainable solution for agricultural. And centre pivot or any other irrigation system should not only have the function for irrigating, but also can increase your yield by less cost. That’s what agnFlow team works for.

This Irritech 4 wheel towable pivot was upgraded by agnflow teat to meet with the Australia local market requirements, with the special designed towable kit, which is every easy for just one person to change the pivot to towable function, we assembled it with Senninger LESA sprinkler package, which will have the more efficiency for the water output. More details contact with agnflow team direct.

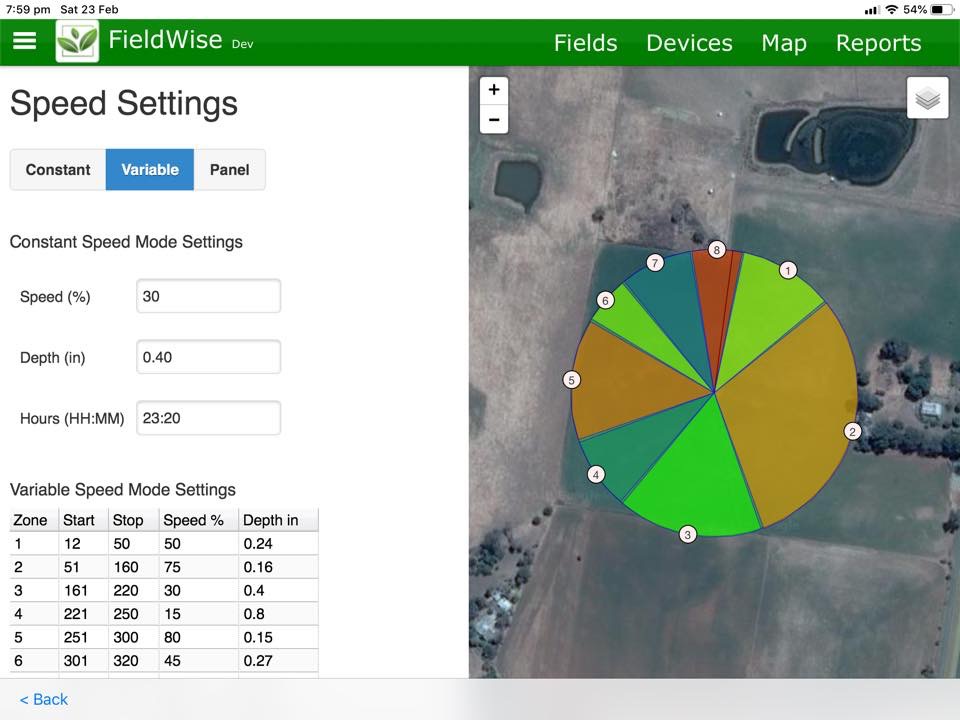

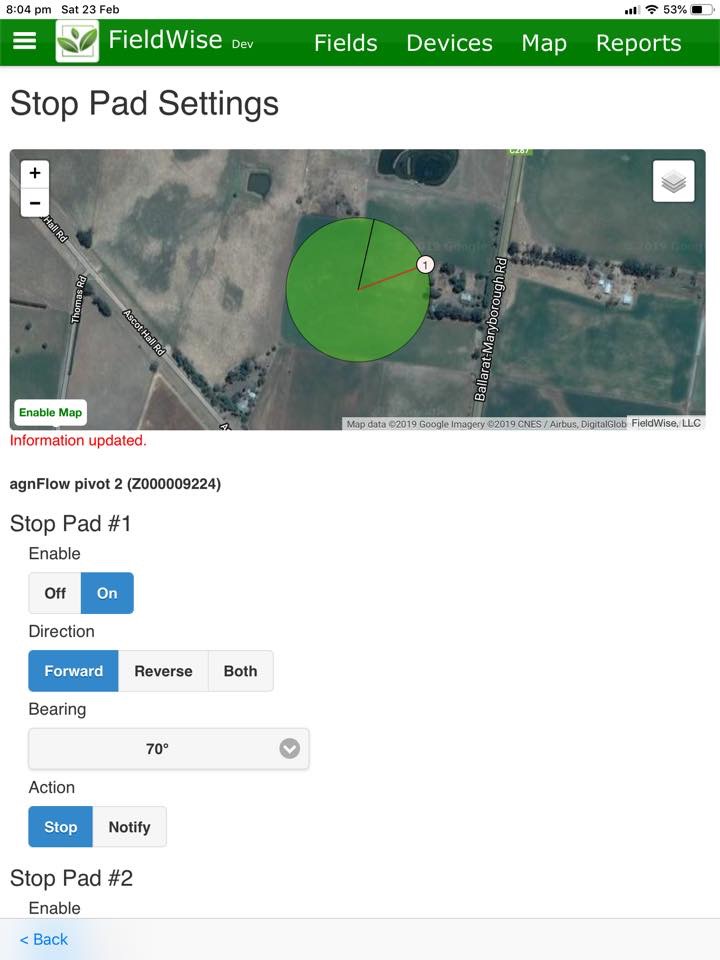

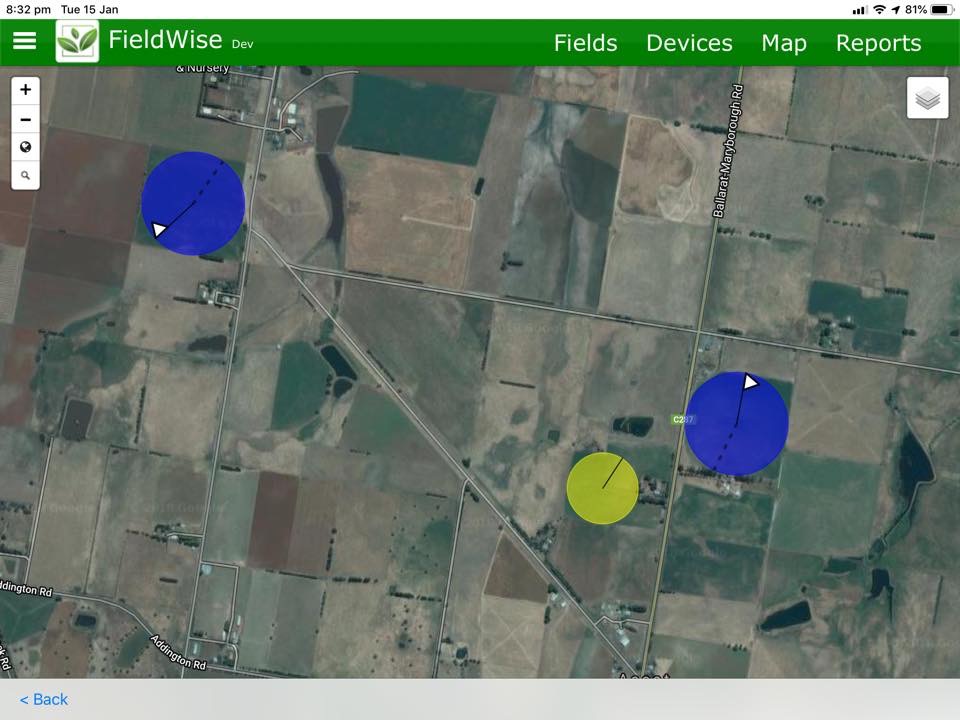

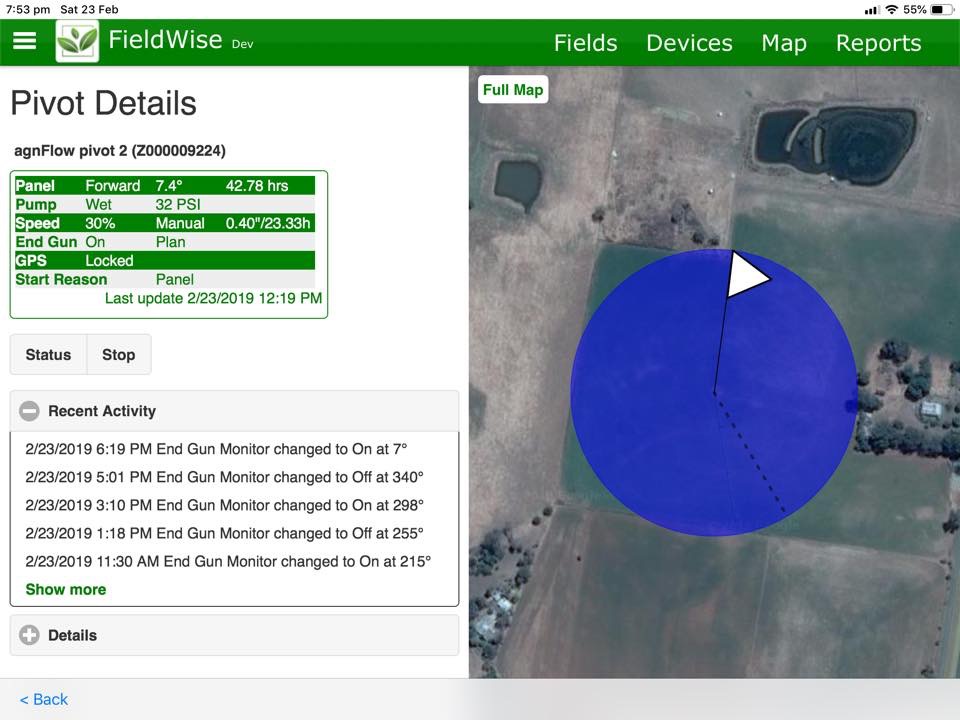

Looking for a solid center pivot control system. FieldWise is now having numbers of these out in the field and working well.

FieldWise Pivot Controller utilizes your existing main panel saving time and money. It replaces your existing percent timer, while keeping the rest of your panel intact. It also offers features unmatched by any other brands, including SMART START. Combined with the FieldWise Portal, the Z5 creates the most enhanced experience that money can buy.

Please send us a message if you would like to know more information.

This 5″ mini centre pivot was put up at QLD, with very good quality galvanised 5″ pipe and structures, if you have a small area need to irrigate, contact with us, we will give you the most cost effective way to go.

This is the second Irritech centre pivot we put up at QLD, running with UMC centre drive and gearbox, Komet sprinkler and end gun package, if you are looking for a V style centre pivot or lateral move irrigation system, contact with us.

Source: Original from Senninger published as “The Hot Topic in Pivot Irrigation: LEPA Close Spacing.” Irrigazette.March 2018.

Global issues like declining water availability and high energy costs are becoming a major concern for irrigator in a world affected by dwindling natural resources.

Growers know that more efficient farming practices and irrigation technologies are needed to keep farm profits sustainable, and are experimenting with new ways to enhance current technologies.

American growers looked at LEPA (Low Energy Precision Application) technology, which was developed in the 1980s, and began testing different ways to use these sprinklers heads.

The technology was already known for its ability to reduce wind-drift and evaporation loss dramatically, so growers began installing this technology in new ways to see if they could increase the benefits.

What began five years ago as an experiment is now an award-winning technology found on farms across Western and Central United States. Now known as LEPA Close Spacing, it is gaining interest outside the USA in Mexico, Brazil, South Africa, and the Middle East’s dry regions, areas where water is regulated, and among forward-thinking growers looking to produce good yields with significantly less water and energy.

UNDERSTANDING LEPA CLOSE SPACING

LEPA originated from a collaboration of researchers from Texas A&M and Senninger Irrigation, a U.S. sprinkler manufacturer, The applicator was designed to deposit water near the soil surface at low pressures- about 18 to 24 inches above the ground- to help prevent wind-drift and evaporation. Cotton growers originally used it in the western high plains of the United States.

In those early LEPA systems, applicators were mounted far apart to irrigate every other furrow. Since this precision application wetted less than half the soil surface, it helped reduce the effects of evaporation, making LEPA 95% efficient in water use.

The new Close Spacing method adjusts the spacing between heads to 40 inches or less between heads. This adjustment allows growers to maintain the benefits of lower wind-drift and evaporation loss and reduced pumping costs while also obtaining:

LEPA Close Spacing has proven so effective that in 2017 the Irrigation Association selected “Close-Spaced LEPA Installations: Saving Water and Energy and Increasing Yields” as the winner of their new Vanguard Award. This award was launched in 2017 to honour a project executed by a team of individuals, companies, organisations or other group entities that have executed an innovative installation project in the irrigation industry.

FIRST-HAND EXPERIENCES

Vanguard Award participant, John Maurer from Triple D Ranch, Dyer Nevada (Longitude: 118.01, Latitude: 37.615, Elevation: 4,898 ft,) discovered LEPA Close Spacing bubblers outperformed standard sprinklers over alfalfa. The climate there is windy with little to no rainfall and very low humidity. The primary soil type is heavy silt clay loam.

LEPA Close Spacing bubblers produced an average of 21.5% more bales and tonnage by 6.5% during four cuttings over the season on three center pivots. The grower attributes these yield increases to the water application rests on the soil surface and slowly infiltrates, producing lateral water movement in the soil and leaching of salts beneath the root zone.

“The groundwater basin here is depleting like most in any heavily irrigated area. It became a concern. So when we started using these and saw what they would do to cut that out, that was a big motivation for me, because it’s all about efficiency. We found out real quick that we’ve got more water in the ground and that we could actually cut back on the amount of water.” said John Maurer.

“We started seeing the difference in the hay growth. Very seldom do we ever get more hay second cutting than first. On one particular field, we put the bubblers on right after the first cutting, and for the second cutting in thirty days, we had forty more bales on one pivot.”

He continued, “This year when we got the soil samples back, we flushed out a bunch of sodium. We’ve gone from like 2.6 down to 1.6, which is pretty substantial. It was the first time that we’ve ever been able to move salt. Now that we have the ability to push water down and flush it out of the root, we can move off salt. I’m excited about what we’re going to be able to do to these fields as we continue to push the water into them.”

On another Vanguard Award participant’s farm in Mingo, Kansas, (Elevation: 3159 ft, soil type: silt loam) grower Bob Holloway was able to farm 50% more corn( a total of 120 acres) with just 250-300 gum thanks to LEPA technology. “The situation that we were in required us to either give up one irrigated circle or find a more efficient means of irrigating,” he said.

“I found that with the LEPA bubbler system, it allowed us to apply the water we have available in a more productive way. The water that is being applied is resulting in less surface moisture and more beneficial subsoil moisture. This should be all producer’s goal.”

Irrigation distributors also see the benefits and increased popularity of LEPA Close Spacing. Vanguard Award participant Rick Grimes, the owner of Southwest Irrigation in southwest Arizona, stated that almost 99% of their sales could be attributed to LEPA technology. In Arizona and the Imperial Valley, California summer weather brings temperatures of 118-120°F, and ET rates range between six-tenths to seven-tenths of an inch a day. This means a farmer with 320 acres of land will need at minimum 12 gallons of water a minute per acre just to offset the ET rates in June, July, and August.

In their experience, a LEPA sprinkler closer to the ground uses less horsepower and less pressure to achieve the same result as traditional sprinklers that are 3, 4, or 6 feet off the ground. Meaning LEPA Close Spacing lets growers irrigate more hectares and save money because they can put more water on the ground more efficiently and get a more uniform crop with it.

According to Rick Grimes, “30-inch[76cm] spacing will come out traditionally between 98 and 99% uniformity and distribution of water applies. You can’t get that with the sprinkler that’s ten fee [3m] apart and five fee [1.5m] off the ground.”

Rod Stilwell, another Vanguard Award participant, has been with American Irrigation in Garden City, Kansas, since the year 2ooo. Weather conditions in this area are usually windy and dry. “The main crops around here are corn, wheat, soybeans, milo, alfalfa, and potatoes. With Close Spacing, growers are seeing that they can shut down their systems more often, therefore saving water and energy. It’s cost-effective way to produce good yields.” he said.

MAKING IT WORK

LEPA Close Spacing systems work better in relatively flat fields with a slope no greater than one percent. Circle planting is recommended to keep the applicator entered in furrow, which not only works to control run-off but also to avoid wetting the crop canopy. Strip-till and no-till practices further help keep the water in the rows and allow for better conditions to preserve the soil moisture, minimise evaporation and protect the row from drying out.

Bubble sprinklers perform at low pressures ranging from 6 to 20 psi, using less energy than conventional low-pressure sprinklers, and operate using fewer litres per than conventional spray nozzles.

LEPA sprinklers available for agnFlow pivot, contact with us see how you can cut your water cost and save power for your irrigation.

This is the 1st irritech centre pivot got shipped and running at QLD in Australia, was put up on 2018 years, on a peanut farm. Our customer is very happy with the quality and how easy for him to use our parts to repair his old Valley pivots.

To buy and install the Center Pivot or Lateral Move irrigators is a big investment for farmers at the start stage of planting. By the time of use or bad water conditions, rainstorm or some of other reasons, some parts of pivot will be damaged, such as pipe, gearbox, centre drive, tyres etc., need to be repaired otherwise will effect when irrigating season come and could make a big lost for farmers. Depend on the current market situation, almost centre pivot manufactures want to push to sell the whole pivot system instead of repair broken pivot for farmers , and cost is very high if the farmers want to repair. So to save the cost and bring back the value to our farmers, AGNFLOW build a good relationship with our manufacturer to supply the aftermarket pivot span pipe and parts for farmer.

One of our customers from QLD, plant the peanut and fed cattle in his farm. He got a Valley pivot used for more than 15 years, but the first 3 spans pipes all rusted, instead of buying a new centre pivot, he is prefer to repair it at a reasonable cost as the rest parts of machines are all good. AGNFLOW gave them the best solution to saving cost.

If you have any pivot need to be repair, welcome to contact with us.

Planting and spraying season is upon us, and as farmers plan for irrigating crops, farmers need to consider what they are asking of the centre pivot around the countryside. The pivot is the only piece of machinery that a farmer owns that sits out in the elements 365 days a year. The pivot does not get the opportunity to spend the winter in a shed like the other machinery is a substantial investment, and needs to last for many years, performing when the farmer needs it most.

AGNFLOW want to remind farmers that performing proper care of the pivot will help their bottom line by providing a greater return on investment. Here we give the checklist you need to check with your pivot before your plant season.

If all above list are good, you should be confident to run your pivot, if you need any help, welcome to contact with our AGNFLOW service team.

More updates from one of our NSW Irrigation Project site. After all the hard work of our AGNFLOW team down, all of 6 centre pivot were put up successfully, which include 2 fixed centre pivot and 4 towable centre pivot. Also we have finalised the water damn suction part, pump station for those 6 centre pivots, and underground main for 2 centre pivot which were already start irrigating for 1 month, the land changed so much comparing before and after using those centre pivot irrigator. There didn’t plant anything before as the bad water sources, now our farmer planting canola and barley, the below photo is a part of farm planted barley after irrigated with our new centre pivot. The farm look so green and vibrant now, hope our customers will have a good harvest this year and on-going seasons.

center pivot and later move system are very effective irrigator for saving water if you have very limit water sources to use, and will make our farmland more powerful and valuable.

There are more underground pipeline works need to be done, we have our own excavator, trencher, tele handler etc. gives us lots help and make our earthwork much easier and quicker.

Thanks for our team members who keep working on this project.

Anhui Irritech Agricultural Equipment Corporation Limited is a high and new tech enterprise, professionally engaged in R&D, production and sales of irrigation machines and crop protection equipment used in large-scale farmland. Focusing on the labor saving, water saving, power saving and increasing yield, Irritech independently research and develop pivot and linear and other automatic irrigation system to offer the customers together with the professional before and after sales service.

Irritech has passed system management as ISO9001, ISO14001, OHSAS18001, Irritech products has certified “water saving equipment”. One fully automatic production line guarantee the accuracy of cutting and welding, and guarantee the annual productivity of 162500m tubes for pivot and linear, at the same time, ERP system ensure the internal manufacturing and logistic quality.

Irritech was public in 2015(stock code is 835416). Irritech products have been successfully installed and used in most provinces in China to irrigate wheat, corn,potato,alfalfa,sugarcane,flowers, and fruits.

For Australian market development, AGNFLOW is the national distributor of Irritech parts, and the dealer for Australia mainland market, any enquiry about Irritech products, welcome to contact with our AGNFLOW team.

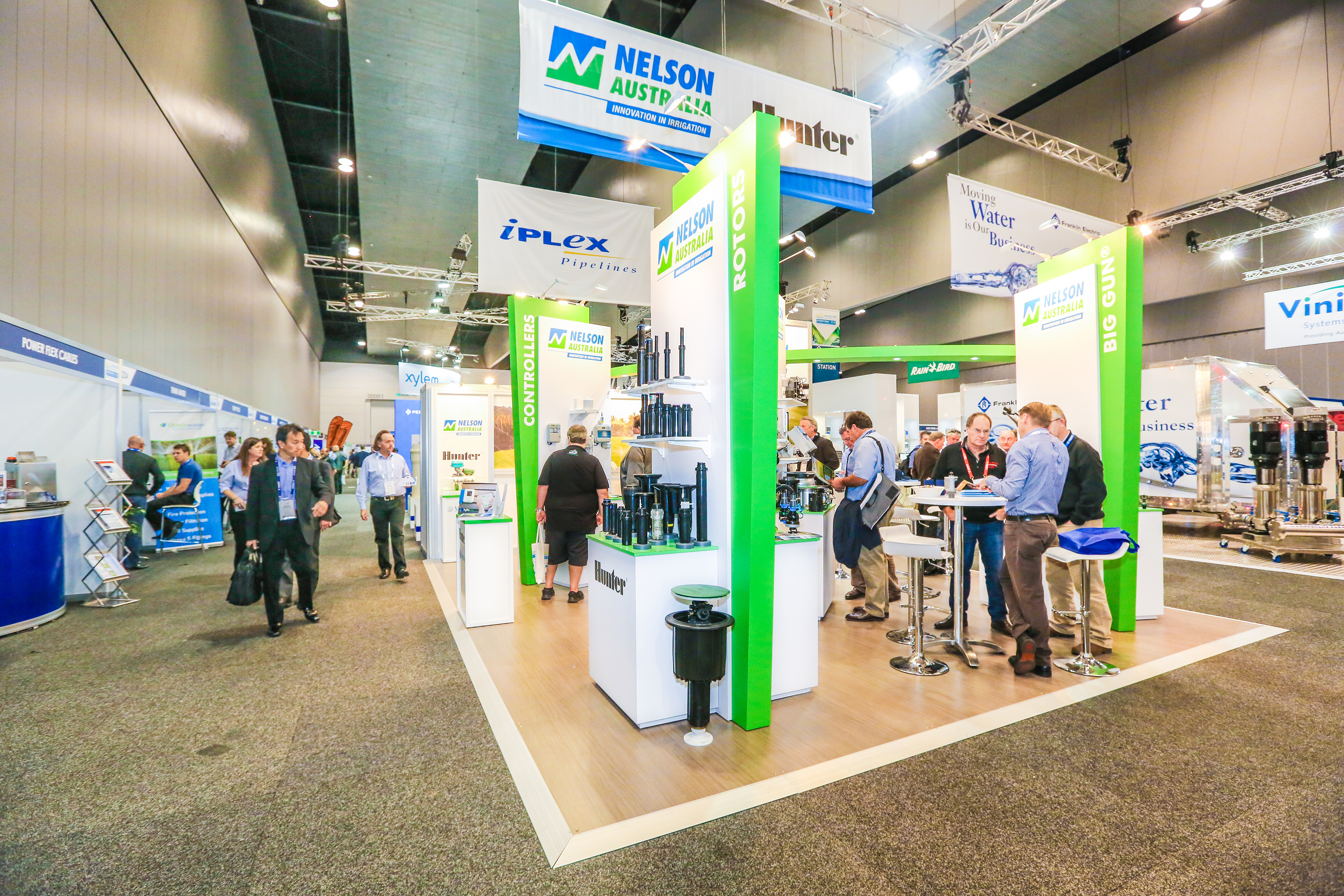

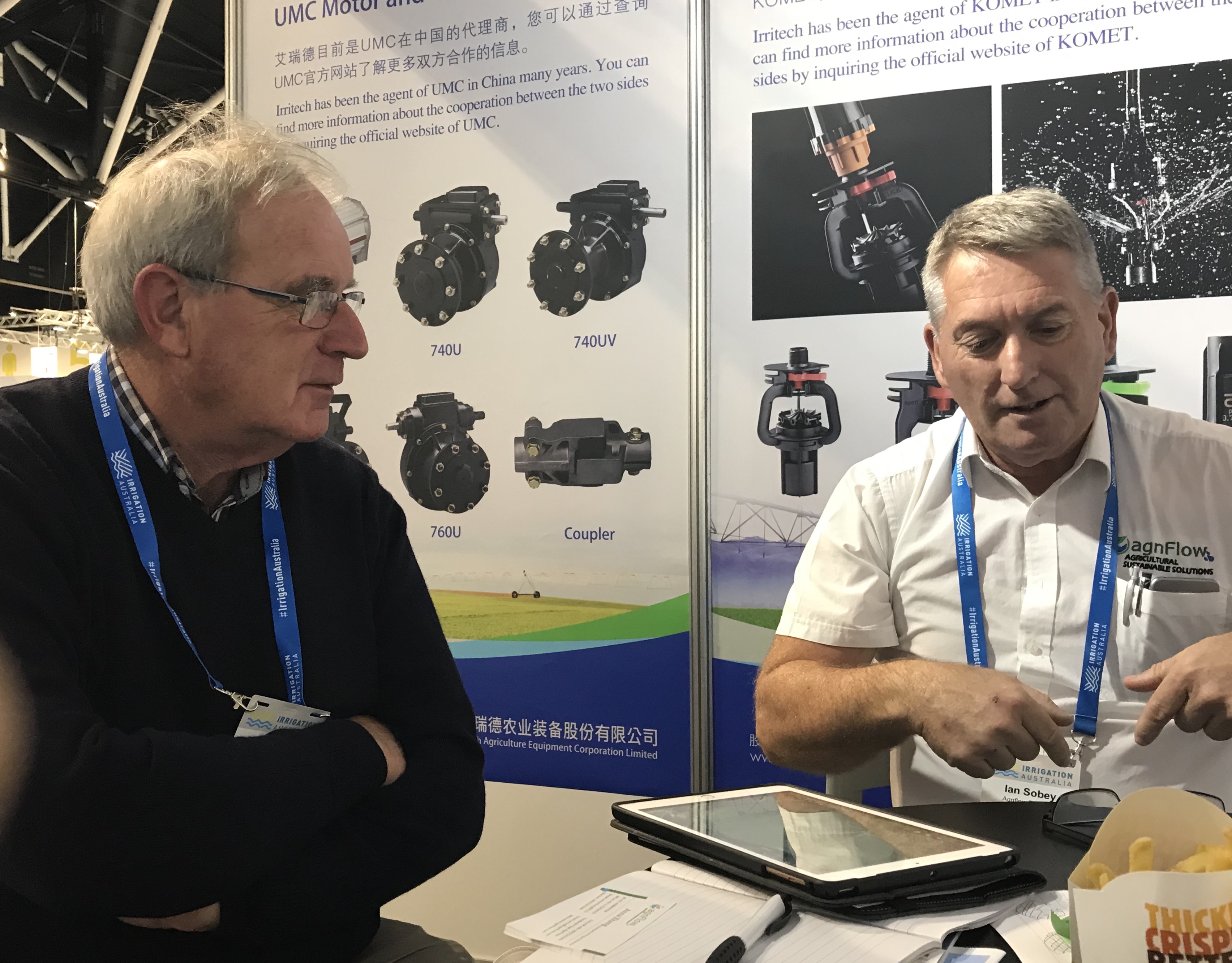

Irrigation Australia International Conference and Exhibition was hosted at International Convention Centre (ICC) Sydney from 13th – 15th June, 2018. After eight years, the conference returns to Sydney, bigger and better than ever. Thi is the only conference in Australia that is solely dedicated to advancing and promoting the entire irrigation industry value chain, presenting issues relating to, or impacting on irrigation in Australia. With the theme”Addressing the Big Issues”, this year’s conference focus on five keys themes:

AGNFLOW team very glade to be invited to attend this show by our China partner Irritech company, it’s a good chance to catch up with our old friends, and to learn the latest technologies and products in this irrigation industrial, which will help our AGNFLOW team to use the best quality products ensure supplying the better service to our farmers for irrigation and water saving.

Awesome Irrigation! this week the team from agnFlow commissioned another 1200m wide lateral for winter cropping This one is watering up canola working on a field of 3Kms long putting out 25Ml per day. This system is a twin for alongside it is another 1200m system that’s currently watering up winter wheat also working on a 3Km. To see two systems side by side covering 2.4Kms wide putting out 50Ml per day is something special. These units run with the latest John Deere engines, Cornel run dry pumps, Clements self-cleaning screens.

We have been lucky to have the opportunity to put this together. Its more pleasing to work with farmers who have had the vision to want something like this and happy to listen to experienced advice to get it.

Our Project Director Ian Sobey said, while this project still in the making it involves turning old much out-dated rice and border cheek layouts into an extremely efficient irrigation upgrade. The water savings are enormous which is becoming more and more important with the cost and availability of water. This large scale spay irrigation is becoming more and more popular as farmers change the way in which they use their irrigation water, especially changing from summer to winter cereals as in this case. Low pressure spray irrigation with high water uniformity is the right choice for large scale projects like this.

Proper planning, skilled contractors are the backbone of any good project but without good sound advice it’s hard to bring projects together. If you would like to discuss more about large or small irrigation upgrades then please talk to us, we have the knowledge and experience with large or small projects.

Agnflow just completed a double pump set as a part of a large overall irrigation upgrade North of Deniliquin. This large project involves 6 center pivots, 10Kms of underground main and five new pump sets.

Agnflow is well experanced in large scale projects and can offer a full turnkey approach for any size upgrade.

More to follow on this great example of doing more with less water soon.

Recently Agnflow completed a pivot project in Gippsland. The project was set around replacing an old tow sprinkler system with two center pivots and new pump controlled with a VFD to maximize energy savings.

This will be a life changing upgrade as not only there will be a huge difference in labor required to irrigate the farm but a huge savings in energy costs. All round this is a very efficient project.